Micromechanical testing of composite materials by FIBRobotics reduces waste and speeds up the testing process

MembersA new member to the ExpandFibre Ecosystem, FIBRobotics, is a start-up with its roots at the Technical University of Tampere in Finland. FIBRobotics is specialised in testing fibre and fibre-reinforced materials with their unique, patented sample preparation solution which requires extremely small amounts of samples to characterise the properties of material. The company helps research institutes and companies developing new materials to speed up the testing of mechanical properties in novel materials and provides them with more accurate data on the feasibility of the material for their needs.

We had the pleasure of talking to FIBRobotics CEO Olli Tanhuanpää andCTO Markus Kakkonen about their company and their expectations on joining the ExpandFibre Ecosystem.

Unique micro-scale testing enables macro-level modelling

Olli and Markus start by explaining the benefits of micromechanical testing for scientific and industrial customers.

From the scientific point of view, biobased and green tech materials are very much in demand at the moment. With the patented sample preparation method developed by FIBRobotics, the scientists only need to provide a few grams of the sample to learn about its adhesion properties. The time and resources spent on achieving a large number of statistically reliable testing results can be dramatically reduced with the FIBRobotics equipment. The future modelling of the materials will be done on a micro-scale but could be as accurately correspondent to the macro-scale model. This is only possible with micro-scale measurements that FIBRobotics offers.

The benefits of measuring with the FIBRobotics devices for the industrial-scale R&D is that industry actors can assure the quality of their material from single fibres, which translates into significant reductions in waste. Micromechanical testing methods can thus enable and accelerate the introduction of new materials and components to the market.

Testing methods of fibrous materials with eyes on biomaterials

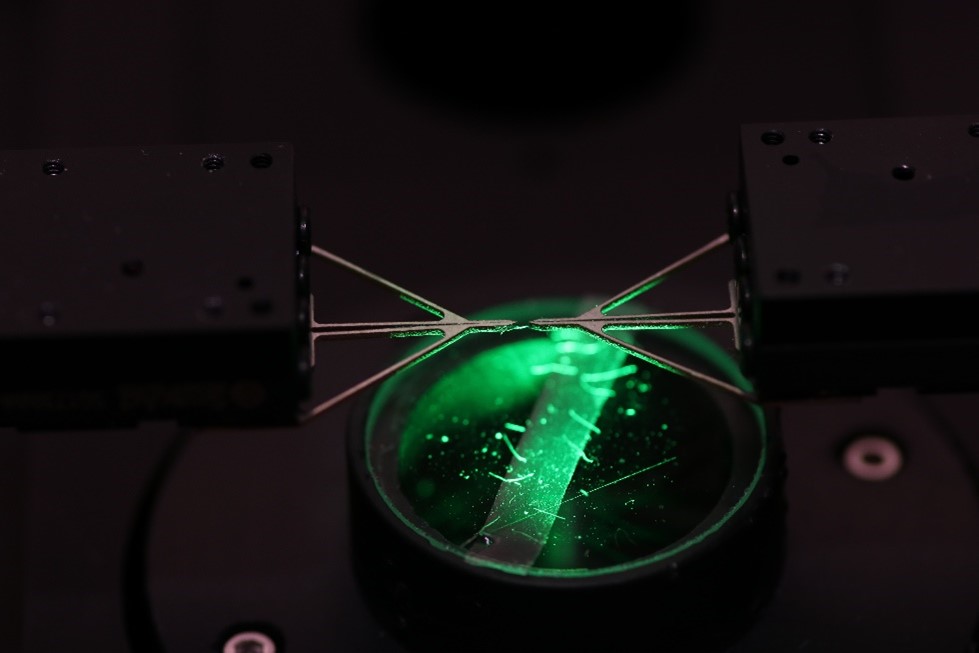

The short fibre testing platform from FIBRobotics can provide a 3D reconstruction model for natural fibres, measurements of single pulp fibres in expected temperatures and micromechanical testing of fibres. FIBRobotics can provide their large customers with customised testing equipment, but also provide testing services to those customers who do not require constant testing or equipment of their own.

FIBRobotics is mainly focused on fibrous materials testing, e.g. glass fibre, carbon fibre and aramid, which are used in aerospace and military applications. Customers are developing solutions to accelerate the green transition, and this is the current trend in the market. This is bringing in more and more biomaterials such as cellulose fibres and lignin-based materials for testing. Biomaterials are future materials, and FIBRobotics is also keen to help in improving them.

FIBRobotics designs and assembles their equipment themselves and develops the required software based on their customers’ needs. The expertise of FIBRobotics also lies in their ability to utilize, combine, and develop software to commercially available actuators for micromechanical testing. The company also provide strong expertise on characterization of materials, and work closely with several universities whom they have helped with publications on the topic. In turn, publications help demonstrate that the FIBRobotics micromechanical measurement methods really do their job in identifying the feasibility of the new materials.

Looking forward to collaborating with the ExpandFibre ecosystem members

Olli and Markus hope that joining the ExpandFibre ecosystem will for its part make their testing methods better known among the ExpandFibre partner organisations and beyond. Surely, many of them are looking for replacements to fossil-based materials but may not be able to test their characteristics in such detail and speed as they would like to.

Metsä Spring has already been in contact with Fibrobotics to develop automated tensile testing platform for measuring cellulose textile fibres. This new device would require minimal effort from technician and free their time to other tasks. Early proof of concept measurement has been made and the next step is to build a prototype device.

Olli Tanhuanpää concludes: “Our testing equipment is designed to optimize the testing process. What with macro-scaled testing could take even months or years, our equipment can define the fibre characteristics in a matter of days! Reducing waste is one of the most significant impact we make. The better our understanding is on the composites, the more optimized can the final parts be. This understanding can make a big difference to the whole value chain, and we are looking forward to bringing our contribution to the actors of the ExpandFibre ecosystem.”

More information: https://fibrobotics.com/