LigninReSurf project advanced the potential of lignin as one of the key enablers in the transition towards a more fossil-free society

ProjectsThe three-year Novel Fiber Surfaces Functionalized by Lignins (LigninReSurf) project was coordinated by Åbo Akademi University during 2021-2023. Joining Åbo Akademi for the Business Finland funded co-research project were multiple pioneering companies from the fields of biorefining and biomaterial development – CH-Bioforce, MetGen, St1, 3D Tech, Kemira and Mirka. Fortum represented ExpandFibre in the project's Steering Group. The project also had two very interesting international collaborators and supporters from BOKU University in Austria, and Université Montpellier in France. The project aimed to provide knowledge and solutions to all industries involved within the ExpandFibre Ecosystem. The project envisioned that a more resource-efficient and bio-based value chain will facilitate the transition of the Finnish economy towards a more carbon-neutral economy replacing traditional fossil-based petrochemicals.

LigninReSurf project’s coordinator Prof. Chunlin Xu from Åbo Akademi’s Laboratory of Natural Materials Technology, together with Dr. Lari Vähäsalo, Co-Founder and R&D Director at CH-Bioforce, joined the ExpandFibre team to discuss and reflect on the recently finished project and its key outcomes. To kick things off, Prof. Xu wanted to extend his sincere thanks to everyone who had recently joined the project’s public seminar on Feb 6th, 2024, organized as a hybrid event at Åbo Akademi in Turku: “We had over 80 participants in total joining the seminar in person and following the presentations online. It was a highly successful event, and it was great to see so many fellow lignin lovers.”

Background to the work

The fundamental motivation for the project was to advance the overall understanding on the very complex structure of the natural polymer lignin making up approx. 30% of plant dry mass. Better understanding of its structural complexity could lead to an overall improved utilization of lignin – an abundant natural polymer, that is currently mainly burnt for energy.

One of the most potential exploitation areas for lignin is replacing fossil-based materials, such as plastics, in multiple end use areas. For example, replacing single-use plastics with more sustainable bio-based alternatives, such as lignin, would have enormous environmental and societal benefits globally – it has been estimated that by 2015, human beings have produced 5.7 billion tons of plastics, of which 4.9 billion tons have been discarded into the natural environment.

Åbo Akademi was the principal investigator of the Business Finland funded co-research project – led by Prof. Xu and Prof. Patrik Eklund – with LigninReSurf having a total project budget of little over €1 million and 70 % of it funded by Business Finland. International supporters BOKU University (analytical method development for lignin) and Université Montpellier (membrane application and testing) were not eligible for public funding through Business Finland but acted as supporters of the work carried out by the Finnish partners.

Outcomes and impact of the project

Prof. Xu described the key impacts of the project: “As a co-research project, LigninReSurf had two key outcomes. Firstly, advances to lignin science and to the overall understanding of the complex structure of lignin were elementary, complimented by the very important educational component of the project. We had four Master thesis works linked directly to the project, two PhD researchers defended their thesis works that were also directly linked to the project. In addition, we had two additional PhDs that had a partial participation to the project.”

Prof. Xu described the lignin science aspect in little more detail: “The main target for us was to understand the correlation between the structure of lignin – a complex polymer consisting of a vast mixture of molecules – and its performance in various end use environments. Due to lignin’s complicated structure, this has truly been a major challenge, and LigninReSurf helped us to advance the basic understanding further. There is vast interest in lignin as a biomaterial as its very abundant in plants, and most of it is currently simply burnt to energy. With LigninReSurf, we were able to assess various chemical modifications processes for lignin, as well as identify better which could be the key products manufactured out of it in the future, and which value chains could be the most probable and feasible moving forward.”

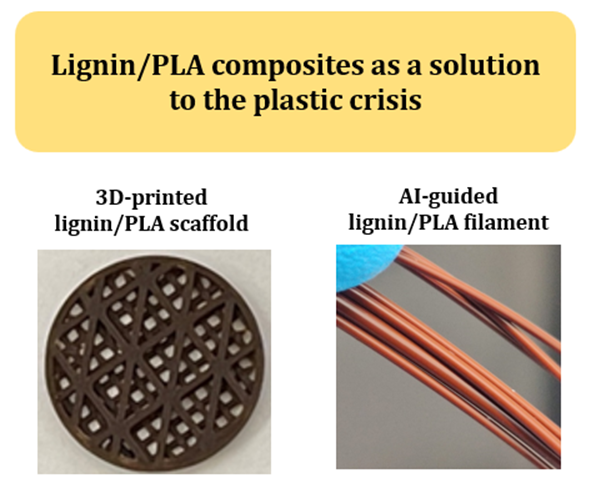

Figure 1. Lignin/PLA composites prepared during the LigninReSurf project (image used with permission)

Dr. Lari Vähäsalo from CH-Bioforce, a Finnish company developing the Bioforsense biomass fractionation technology, provided key observations on the relevance of the LigninReSurf project. As background, Lari detailed that CH-Bioforce are in the process of starting to build a 27 kton/a factory in Raisio, Finland, using oat husks as raw material for their own biomass fractionation technology to produce valuable biomaterials: “In our discussions with offtakers, cellulose and hemicelluloses have been very attractive, but finding offtakers for lignin has been slightly more challenging. Although the cosmetics industry has shown some interest, we need to find a wider selection of potential applications for lignin. For this brainstorming of ideas, the project was very beneficial. In general, the range of ideas that have popped up in my head as result of these discussions during the project enabled us at CH-Bioforce to contact specific companies with certain applications in mind.”

Lari added: “We always have to look at the big picture and carry out detailed technoeconomic analyses and feasibility studies when planning to substitute certain components with lignin. For these considerations, the project provided us with a lot of know-how. Sulphur-free lignin is one of the key components that our future factory will produce, so the attainable market price of lignin is a key component for our business. The LigninReSurf project provided us with additional insights that through slight modifications, lignin can be valorised to have a significantly higher market price compared to unmodified lignin. This is of course highly interesting for us moving forward with our lignin product portfolio.”

According to Lari, many industries are very interested in lignin: “Plenty of industries would love to see a bio-resin made completely of lignin with a 100% substitution of petroleum-based phenol with lignin. Some companies are already providing bio-resins which only have a 20 % substitution rate of phenols with lignin, for example. It is enlightening to see how many possibilities there are for lignin across so many industries.”

Lari also reminded on the current challenges facing lignin commercialization for CH-Bioforce: “We have two years left until our new factory starts production, but there are many things that need to be solved in the meantime. IPR and all legal issues are hot topics in the lignin field with many potential hurdles. What also needs to be noted is that lignin is a hazardous transport material. If the granule size of the produced lignin is too small, it may cause a dust explosion hazard. This translates into potential issues with airplane transportation, for example. Chemical modifications, such as those researched during LigninReSurf, help to adjust the granule size of the produced lignin, easing potential restrictions for transport and the hazardous material status.”

Clear path forward with collaboration

Collaboration was a key aspect of the project and its success, as highlighted by Prof. Xu: “The collaboration throughout the three project years was very smooth, and I particularly appreciated the valuable input from the industry partners. All the partners were very eager to help and the steering group meetings as well as the workshops on set topics were extremely fruitful. We at Åbo Akademi were also able to have one-on-one regular discussions with industry representatives, which were highly appreciated.”

Lari agreed and continued to reflect from his perspective: “Both collaboration and communication were exemplary during LigninReSurf. What people might not always realize is that this kind of publicly funded projects are key enablers in bringing companies together, which in the long run is highly beneficial. Business Finland is naturally interested in the increased export volumes of Finnish companies, but this can only be achieved once you have a feasible product or service that can be exported. It’s easiest to start collaborating with local partners who you know well and advance from there. Building robust networks with people in different industries is elementary for growth. This kind of projects are important, not just for the R&D, but also for building long-lasting relationships with people across industries. For us at CH-Bioforce, our fundamental aim is to have a clear path forward for our lignin, and use it in the best possible applications, and not just burn it or dump it into asphalt, for example.”

What comes to continuing the excellent work of LigninReSurf now that the project has ended, Prof. Xu mentioned that wheels are very much in motion for future work related to lignin development and exploitation: “We have been planning a continuation for LigninReSurf, and during the project we identified very interesting new collaborators from Helsinki University and University of Turku. Helsinki University has great expertise in issues related to circularity and University of Turku has worked with artificial intelligence within lignin research, which is very interesting. Our primary aim is to submit a plan for a co-innovation project for Business Finland with the main ambition to up-scale testing to pilot scale. Overall, the company members within the LigninReSurf consortium are highly interested in advancing the application development for lignin. We have also been looking to extend our existing international networks even more widely throughout Europe, with hopefully an EU project sometime in the future.”

To finalize the discussion, Prof. Xu extended his thanks to ExpandFibre and remind the Ecosystem partners on lignin-related collaboration possibilities: “The support for the project through ExpandFibre has been very much appreciated, and we are very much looking forward to what’s to come next once ExpandFibre comes to its close later this year. In case any Ecosystem members are interested in lignin research or seeking potential applications for lignin, we are very happy to discuss things further, and to develop this very potential natural material together.”

More information: LigninReSurf website including presentations from the Lignin Seminar Day on 6.2.2024.