LigninReSurf consortium project develops high performance copolymers and materials based on lignins from Finnish biorefinery processes

Projects NewsThe ultimate goal of LigninReSurf project is to develop high performance lignin-based copolymers and materials for novel bio-based applications, i.e., porous membranes, new aqueous dispersion coating formulations, and new thermoplastic materials. The project will use lignin from Finnish biorefinery processes, which are currently targeting major products, such as fibers and biofuels and are underutilizing lignin.

Plastics are widely used for packaging and other applications in our daily life. However, single-use of these applications have led to accumulation in landfills, oceans, waterways, and other natural environments. The plastics can further enter animal and human bodies from the environment, threatening our health. It was estimated that by 2015, human beings had produced 5.7 billion tons plastics and of that, 4.9 billion tons were discarded into the natural environment. Plant biorefinery is a renewable and sustainable alternative to the current petroleum-based industry and plays an important role in addressing the UN Sustainability Goal. Lignin accounts for up to 30% of dry mass of plants, but so far, most of it is burned for energy.

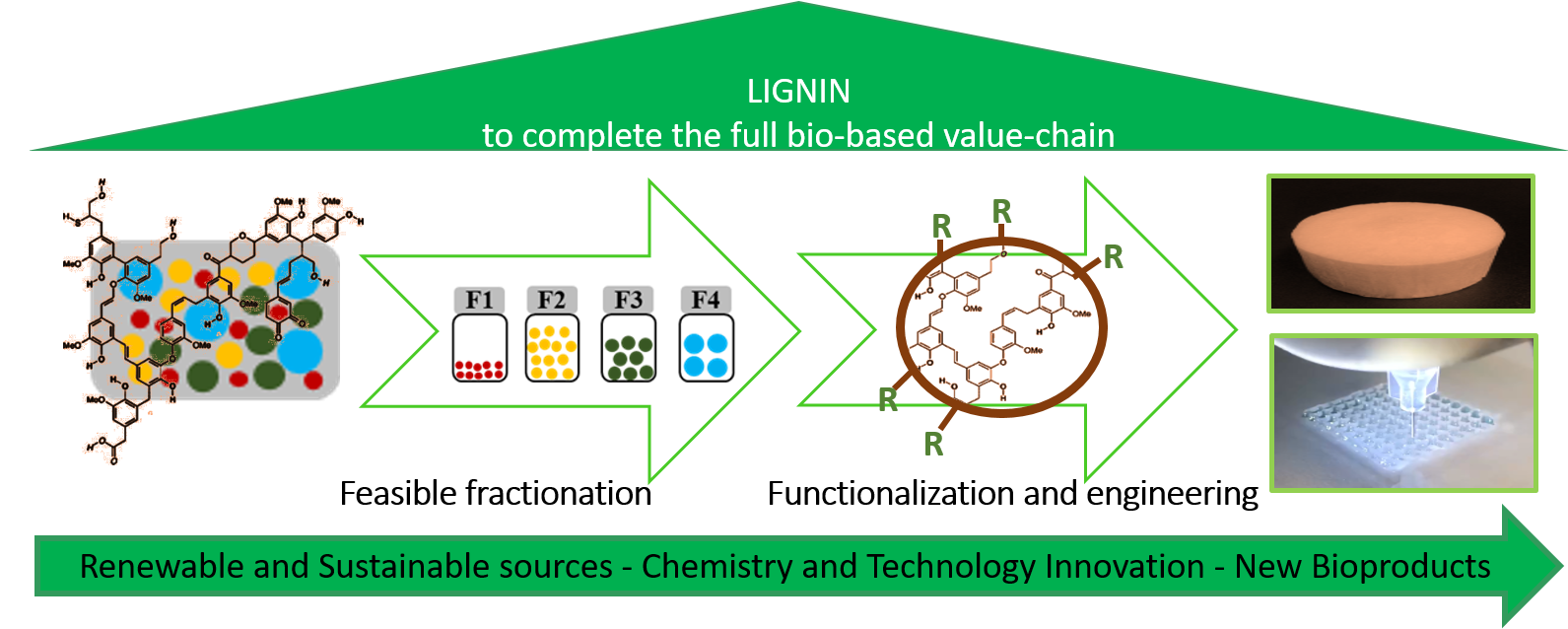

The LigninReSurf concept.

The LigninReSurf consortium project, which is part of the ExpandFibre ecosystem, plans to use the relevant lignin streams from Finnish biorefinery processes as raw materials to apply lignin-refining approaches to achieve well-defined fractions with well-characterized structures. Green sustainable approaches, such as using enzyme as well as novel chemical approaches, will be developed for tailoring these lignin fractions to novel bio-based porous membranes. These membranes will be used for water purification, new coating formulations for functional surfaces and packaging as well as other bioplastic materials for consumable products. Moreover, new 3D printing approaches will be explored and open vast business potential for lignin to be used in manufacturing those fiber-based products.

The consortium coordinator, Prof. Chunlin Xu from Åbo Akademi University has introduced the consortium, saying: "The consortium also includes partners from BOKU University (Austria) and Université Montpellier (France) and industrial partners from biomass fractionation to energy, chemical, and material manufacturers covering the entire bio-based value chain, namely CH Bioforce, MetGen, St1, 3D Tech Ltd, Kemira, and Mirka. We are really delighted that Fortum has joined the steering team and the project is one of first projects that ExpandFibre Ecosystem strongly supports."

The project outcome will provide knowledge and solutions to all industries involved in the ExpandFibre Ecosystem. A more resource-efficient bio-based value chain will facilitate the transition of Finnish economy to carbon-neutral economy and make a strong impact on the environment replacing traditional fossil petrochemicals.

More information:

Professor Chunlin Xu, Laboratory of Natural Materials Technology, Faculty of Science and Engineering, chunlin.xu@abo.fi