Fold project developed a novel folding technology towards future industrial-scale deployment for lightweight design structures and protective packaging

ProjectsAt the core of the Fold consortium was the vision to create a completely new portfolio of industrially foldable products, inspired by the ancient Japanese art of paper folding origami. The products were designed to increase the export volume and enable the opening of new business opportunities for Finnish companies. The primary objective of the project was to further develop a novel folding technology with the potential to be a radical innovation for the paper and packaging industry as well as for other industry areas. The long-term target for the project’s novel folding technology is the eventual industrial-scale production of the first-of-its kind structures for several end use applications contributing directly towards the ambitious sustainability targets of the European Union.

ExpandFibre team had the great pleasure of interviewing Fold project coordinator Jarmo Kouko, Research Team Leader at VTT Technical Research Centre of Finland, as well as project partners Jyrki Loukola, Design Manager at Elomatic Oy and Iiro Numminen, Structural Packaging Designer at Metsä Board.

The Fold project, which ran from January 2022 until end of 2023, was coordinated by VTT Technical Research Center of Finland. Project partners included Aalto University as the second research organisation of the consortium, and eight company partners including influential actors in the Finnish industrial ecosystem: Anpap Oy, Elomatic Oy, Lumene Oy, Metsä Board, Mirka Ltd, Orfer Oy, Soften Oy and Stora Enso Oyj. In total, the project received 2.9M€ public funding from Business Finland.

Background to the Fold project

When initiating discussion on the fundamental motives for the project, Jarmo first mentioned that even though foldable structures were very well-known, including handmade origami structures practised all over the world, the actual machinery for the industrial-scale exploitation of such structures and their vast end use potential was essentially lacking.

Jarmo mentioned that the “Miura fold” or Miura-ori paper folding method, developed by the Japanese astrophysicist Kōryō Miura, was particularly influential for the research and development work carried out by the Fold project. Developing machinery, which has not existed prior, was a highly interesting task for Jyrki and the rest of the Elomatic team based in Elomatic’s Jyväskylä offices. Jyrki noted: “Our team’s core knowledge and passion focuses in developing piloting and R&D equipment for multiple purposes. Also, Elomatic as a company has a long history of designing different machines of various sizes. For example, Elomatic had a key role in designing one of the largest cruise ships in the world, the Oasis of the Seas, which was built in Turku.”

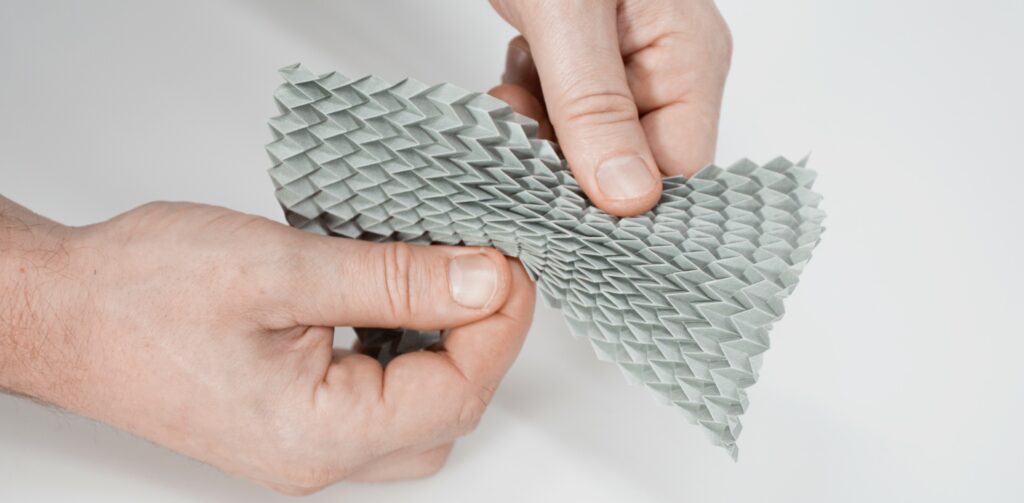

Iiro described the key aspects of the Fold project for Metsä Board as a paperboard producer: “The practise of paper folding, and origami, were very close to my heart as a packaging designer even before joining the project. What was especially interesting within Fold was assessing the future potential of scaling-up folded paper structures and their manufacturing equipment towards industrial-scale. We at Metsä Board see the vast potential of folded paperboard structures in replacing plastic as a packaging material in multiple e-commerce applications. Beautifully folded structures that offer excellent protection through both carefully implemented structural design and the high strength of the packaging material itself, such as paperboard, could be a very interesting combination for high-value luxury packaging applications in the future.”

Figure 1. Small scale Miura pattern (photo from Fold project’s website – used with permission)

Metsä Board is naturally very interested in the future co-development of packaging solutions from our paperboards based on the Fold project’s technology. Also, the wide-ranging expertise of my colleagues at Metsä Board’s Excellence Centre in Äänekoski was a key enabler in helping us approach the Fold project from multiple angles, as well as speed up the overall development process.”

Jarmo continued to explain on the foundations of the piloting equipment utilized and developed during the project: “VTT together with Elomatic had an elementary role in the development of the piloting equipment itself, and especially ideating on the main concepts around it.” Jarmo noted that VTT and Aalto had originally initiated the work that led to the Fold project during the FinnCERES flagship initiative funded by the Research Council of Finland. “We utilized this prior knowledge as the basis for Fold project, and with Elomatic’s help we were able to develop the original pilot equipment further. Three dimensional structures are especially challenging to figure out, and with endless possibilities for structures, it was extremely important to find the foldable structure with the greatest potential for scalingup to industrial scale, and thus bring real impact for the participating companies,” Jarmo explained.

Key achievements of the project

When asking to reflect on the key outcomes of the project, all three interviewees agreed that the most important result for the project was the actual pilot machine developed during the project. “The machine, or test bench, as it could be also labelled, had its frame already intact prior to the project, but had all of its inside components renewed during Fold. According to detailed patent and literature reviews, the machine is highly unique and has the capability of being turned into a continuously working machine,” Jarmo noted. “By the end of the project, we had the opportunity to present our work at the Dutch Design week in October 2023, where the project attracted a lot of interest and even Queen Máxima of the Netherlands visited the booth of the Fold project (link),” Jarmo remembered proudly.

Jarmo added that the collaboration with Aalto University was superb throughout the project: ”Three different schools of Aalto took part in the activities – School of Engineering, School of Science and School of Arts. This definitely added to the interdisciplinary component of the project. Colleagues at Aalto had an essential role in enabling the project to be present at the Dutch and Helsinki Design Weeks.”

Figure 2. Miura protective packaging (photo from Fold project’s website – used with permission)

Jyrki mentioned that the consortium’s goal was to find a suitable company to purchase the pilot machine, but this search has not been successful yet: “VTT has invested a lot of money to the machine itself and towards the development of the unit processes, which have all been thoroughly tested and verified.”

Iiro also mentioned that the expectations for the functionality and speed of the pilot machine were indeed met during the project: “At Metsä Board, we were naturally interested in assessing the functionality of our paperboards for the machine developed during Fold, and for that work our expectations were greatly met. What was somewhat lacking during Fold was the evaluation of possible end products, but that is something that we hope to focus more on the future.”

Key learnings & next steps

When discussing the potential challenges during the project, Jarmo noted that from his perspective the design of the pilot machine was slightly delayed due to unfortunate resourcing challenges. They had an impact on the total time available for the design work during the two-year project.

Jyrki, on the other hand, wanted to extend his gratitude towards the consortium: ”All project meetings and materials were very professionally prepared, and despite the challenges of COVID-19 affecting face-to-face meetings, the overall feeling of this project was highly positive for me.”

Iiro reflected that the project was in overall a major positive learning experience for him: “I have learned so much, and also shared the key learnings with my colleagues at Metsä Board. This was my first collaborative project of this scale, and most importantly, it has been very easy to be an active member of the Fold consortium. Mostly I’m an independent designer in my day-to-day work, but the collaboration during Fold has been very influential for me. Simulation work, machine design and mechanical engineering are just some aspects of Fold that were very inspiring for me and will undoubtedly have a positive impact on my future work going forward.”

Jarmo explained that due to the immense potential of Fold, it was important to carefully plan the next steps: “We have planned a new co-innovation project funded by Business Finland and we’re currently waiting for the funding decision from the national funding agency. EU project is also an important future step in our plans, which would increase international co-operation even further and open up new business opportunities in the EU for the Fold consortium.”

Jarmo shared his final thoughts: ”The complex theories and mathematics behind three-dimensional folded structures have been widely studied and simulated. For some reason, industrial- scale exploitation of these highly interesting and promising structures has not been successful yet. We are only now truly starting to identify the full potential of these structures better, and our work has only started.”

More information: https://fold-project.com/